Die Casting in Malaysia: A Thriving Industry in Precision Manufacturing

Die casting has become a vital part of Malaysia’s industrial sector, supporting key industries such as automotive, electronics, and consumer goods manufacturing. This metal casting process involves injecting molten metal into a mold under high pressure, resulting in durable and intricately designed components. Malaysia’s strong manufacturing ecosystem, combined with its skilled workforce and advanced technology, has positioned the country as a hub for high-quality die-cast products. Many multinational companies have set up production facilities in Malaysia to take advantage of its competitive costs and well-developed infrastructure. As global demand for precision-engineered metal components continues to grow, Malaysia’s die casting industry is poised for further expansion.

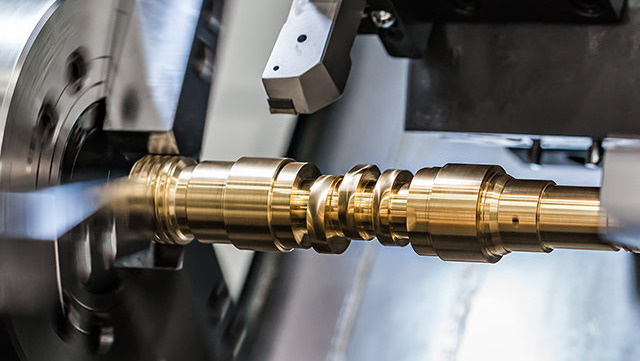

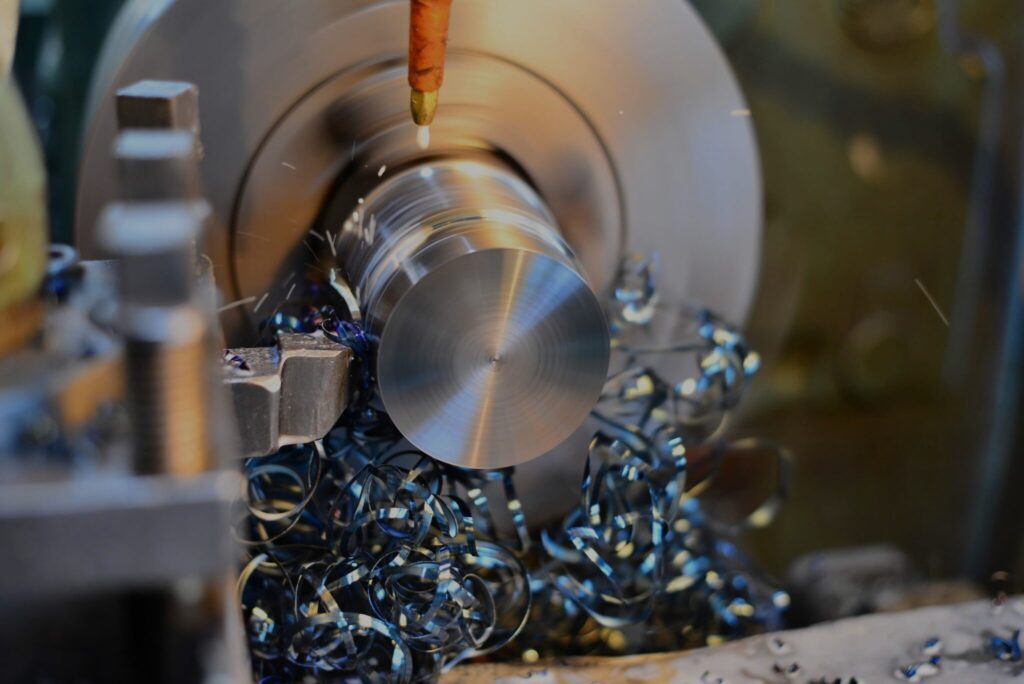

Technological advancements have played a crucial role in the growth of Malaysia’s die casting sector. Many manufacturers have adopted computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to improve accuracy and efficiency. Automation and robotics are also increasingly being used to enhance production speed and reduce errors, resulting in high-quality, consistent products. In addition, companies are exploring sustainable practices, such as optimizing energy consumption and using recyclable materials to minimize environmental impact. These improvements have made Malaysian die casting companies more competitive in the global market, attracting clients from various industries seeking precision-engineered components.

The automotive industry is one of the primary drivers of die casting in Malaysia, with manufacturers relying on lightweight aluminum and zinc components to improve fuel efficiency and reduce emissions. Die-cast parts such as engine blocks, transmission housings, and structural elements are essential for modern vehicles, particularly as the demand for electric vehicles (EVs) continues to rise. EV manufacturers require lightweight, high-strength materials to enhance battery efficiency and overall vehicle performance, creating new opportunities for Malaysian die casting companies. By investing in research and development, these manufacturers are staying ahead of industry trends and meeting the evolving demands of the automotive sector.

Beyond the automotive industry, Malaysia’s die casting sector also plays a significant role in the electronics and consumer goods markets. The electronics industry depends on precision die-cast components for devices such as smartphones, laptops, and household appliances. These products require lightweight, durable parts that can withstand regular use while maintaining a sleek and compact design. Malaysia’s strong presence in global electronics manufacturing has fueled the need for high-quality die-cast components. Similarly, consumer goods manufacturers utilize die casting technology for items such as kitchenware, power tools, and industrial equipment, benefiting from the process’s ability to produce intricate and long-lasting metal parts.

Despite its rapid growth, the precision machining malaysia faces several challenges, including rising raw material costs and competition from other manufacturing hubs. The fluctuating prices of metals such as aluminum, zinc, and magnesium can impact production expenses and overall profitability. Additionally, Malaysia must compete with larger producers in China, India, and other Southeast Asian countries, which often have lower labor costs and greater production capacities. To maintain its competitive edge, Malaysian die casting firms must focus on innovation, quality assurance, and customer service. By developing value-added services such as prototyping and customized production, companies can differentiate themselves in an increasingly crowded market.

Looking ahead, the future of Malaysia’s die casting industry remains bright, driven by industrial advancements and increasing demand for precision-engineered components. The integration of Industry 4.0 technologies, including artificial intelligence, machine learning, and the Internet of Things (IoT), is expected to further improve efficiency and quality in die casting production. Sustainability will also become a key focus, with manufacturers adopting eco-friendly materials and energy-efficient processes to align with global environmental standards. As Malaysia continues to strengthen its position as a leading manufacturing hub in Southeast Asia, its die casting industry will play a crucial role in shaping the future of precision engineering, supporting industries worldwide with high-quality, innovative solutions.